In the dynamic landscape of metal part manufacturing, the demand for flexibility and precision has never been higher—especially for components like drawer slides, which form the backbone of furniture, automotive, and storage systems. Sanyhore, a reputable manufacturer based in Jieyang, China, addresses this need with its customizable drawer slide roll forming machine, a testament to advanced engineering and tailored production capabilities. Designed to adapt to diverse production requirements, this machine integrates cutting-edge roll forming technology with the ability to adjust to specific slide dimensions, materials, and performance standards, making it an ideal choice for businesses aiming to optimize their manufacturing processes.

#Understanding the Customizable Drawer Slide Roll Forming Machine

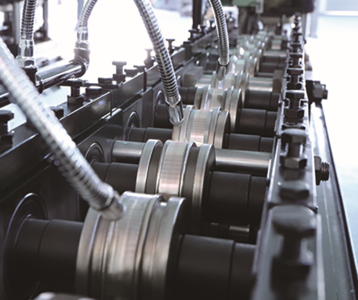

At the core of Sanyhore’s machine lies a modular design that prioritizes adaptability. Unlike standard roll forming equipment, this machine features interchangeable tooling systems, allowing manufacturers to modify parameters such as material thickness (ranging from 0.3mm to 2.0mm), slide length (up to 1.5 meters), and profile complexity. The roll forming process itself is continuous, with a series of precision rollers that shape the metal strip into the desired slide structure in a single pass, minimizing material waste and enhancing production speed. Operators can easily adjust the machine’s PLC control system to match production demands, ensuring consistency across batches and reducing downtime for retooling.

#Key Advantages of Sanyhore’s Customizable Roll Forming Technology

What sets Sanyhore’s machine apart is its focus on both performance and user-centric design. The machine is built with high-strength steel frames and precision-ground rollers, ensuring durability and minimizing wear over extended use. Additionally, the inclusion of automatic lubrication systems and real-time monitoring sensors reduces maintenance needs, keeping operational costs low. For businesses with varying production needs—whether producing small batches of custom drawer slides or high-volume standard components—this adaptability translates to greater efficiency and reduced dependency on multiple machines. Sanyhore’s team of engineers works closely with clients to refine the machine’s specifications, ensuring it aligns with their unique product requirements.

#Enhancing Production Efficiency Through Advanced Engineering

Efficiency is a cornerstone of modern manufacturing, and Sanyhore’s roll forming machine excels in this area. By integrating servo-driven systems and computerized controls, the machine achieves a production speed of up to 30 meters per minute, significantly outpacing traditional methods. The continuous roll forming process eliminates the need for manual cutting or welding, streamlining the workflow and reducing labor costs. Furthermore, the machine’s ability to produce complex slide profiles in one pass minimizes the risk of errors, ensuring each component meets strict dimensional tolerances. For manufacturers scaling up production or diversifying their product lines, this efficiency directly translates to higher output and improved profitability.

#Versatile Applications Across Industries

The customizable nature of Sanyhore’s drawer slide roll forming machine makes it suitable for a wide range of industries. In furniture manufacturing, it can produce both standard and custom telescopic, side-mount, and under-mount drawer slides, meeting the aesthetic and functional needs of modern furniture designs. In automotive applications, the machine adapts to produce heavy-duty slides for vehicle storage systems, ensuring durability and safety. Even in industrial settings, it can form slides for warehouse shelving and material handling equipment, where load capacity and reliability are critical. This versatility positions the machine as a long-term investment for businesses seeking to expand their production capabilities.

#Ensuring Quality and Compliance in Every Run

Quality control is non-negotiable in manufacturing, and Sanyhore’s machine incorporates multiple safeguards to ensure consistent results. Each machine undergoes rigorous testing before delivery, including stress tests on the frame, precision checks on the roller alignment, and performance trials with actual production materials. Post-delivery, Sanyhore offers comprehensive training for operators, ensuring they can maximize the machine’s potential and maintain it effectively. For businesses operating in regulated industries, the machine is designed to comply with international quality standards, such as ISO 9001, giving clients peace of mind that their products meet global market requirements.

#Why Partner with Sanyhore for Your Roll Forming Needs

Choosing Sanyhore means partnering with a manufacturer with decades of experience in roll forming technology. Beyond providing state-of-the-art machines, Sanyhore offers end-to-end support, including on-site installation, technical troubleshooting, and spare parts supply. The company’s team of experts is available 24/7 to address questions or resolve issues, ensuring minimal disruption to production. As a trusted provider of hinge assembly machines, telescopic drawer slide assembly machines, and other metal forming equipment, Sanyhore has the knowledge and resources to meet the evolving needs of its clients.

Ready to transform your drawer slide production? Contact Sanyhore today to discuss your specific requirements. Our team of engineers will work with you to design a customizable roll forming solution that aligns with your goals. Reach out via phone at +86 13425506550 or email at info@sanyhore.com to learn more about how our machines can elevate your manufacturing process.

Common SEO Questions for Sanyhore’s Drawer Slide Roll Forming Machines

1. What makes Sanyhore’s customizable drawer slide roll forming machine suitable for different production scales?

2. Can your roll forming machines adapt to custom drawer slide designs provided by clients?

3. What materials does your drawer slide roll forming machine work with, and what thickness ranges do you support?

4. How does Sanyhore ensure the precision and quality of its roll forming machines?

5. Do you offer after-sales support, including maintenance and operator training, for your machines?