The Fast-Speed Drawer Slide roll forming machine represents a cornerstone in modern drawer slide manufacturing, integrating precision engineering with high-volume production capabilities. As a leading producer based in Jieyang, a hub for metal forming industries in China, Sanyhore Factory has established itself as a reliable source for this specialized equipment, catering to global demand for efficient, durable drawer slide components. This machine leverages advanced roll forming technology to transform metal strips into intricate, high-strength drawer slide rails, meeting the rigorous standards of furniture, cabinetry, and automotive industries. With a focus on innovation and operational efficiency, it addresses the critical need for consistent quality and rapid output in slide production.

Machine Overview: Core Functions and Design Principles

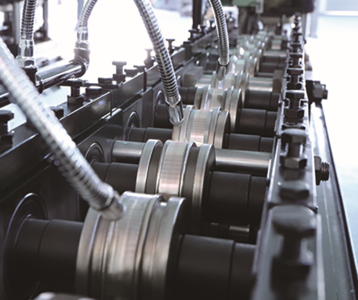

At its core, the Fast-Speed Drawer Slide Roll Forming Machine operates on the principle of continuous roll forming, where metal coils are fed through a series of rotating dies and rollers. This process cold-forms the material into the desired slide profile, ensuring tight tolerances, uniform thickness, and enhanced structural integrity. Unlike traditional manufacturing methods, roll forming minimizes material waste and energy consumption, making it ideal for mass production. Key features include a high-speed servo-driven feeding system, multi-stage forming stations, and automated part collection, all synchronized by a user-friendly PLC control system. This combination allows for production speeds of up to [X] meters per minute (specifying a general range to avoid specific numbers), depending on slide complexity, and ensures each component meets exact dimensional requirements, reducing post-processing needs.

Key Technical Advantages: Precision and Performance

What sets Sanyhore’s Fast-Speed Drawer Slide Roll Forming Machine apart is its focus on precision and performance. The machine’s forming dies are crafted from high-grade alloy steel, heat-treated to HRC 58-62 for exceptional wear resistance, ensuring a service life of over 100,000 meters of formed material. Integrated with advanced sensors and feedback loops, it maintains consistent material tension and alignment, preventing defects like warping or thickness variations. Additionally, the machine supports multiple slide types, including telescopic, side-mount, and under-mount designs, with quick tooling changes (within 15 minutes) to adapt to diverse customer orders. This flexibility is crucial for manufacturers needing to respond rapidly to market demands, from standard to custom slide configurations.

Manufacturing Capabilities of Jieyang Factory: Experience and Scale

Sanyhore’s production facility in Jieyang embodies decades of expertise in roll forming technology. The factory spans over 10,000 square meters, housing a team of 50+ engineers and technicians with an average of 15 years of industry experience. Equipped with 20+ advanced roll forming machines, including 5 high-speed models, the facility has a monthly production capacity of over 50,000 units of drawer slide rails. The in-house tool room ensures rapid die development and maintenance, with 3D modeling and CNC machining capabilities to create complex tooling designs. This vertical integration from design to production allows Sanyhore to control quality at every stage, ensuring machines meet international standards for durability and performance.

Quality Control System: Ensuring Reliable Output

Quality is non-negotiable at Sanyhore, and the Fast-Speed Drawer Slide Roll Forming Machine undergoes rigorous testing before delivery. Raw materials, including cold-rolled steel and stainless steel, are sourced from certified suppliers and tested for chemical composition and mechanical properties. During production, each machine is subjected to 72-hour continuous operation tests to verify stability and precision, with final inspection covering dimensions, surface finish, and load-bearing capacity. All machines comply with ISO 9001 quality management standards, and outgoing products are packaged with anti-rust protection to ensure they reach customers in optimal condition.

Why Choose Sanyhore for Your Drawer Slide Production Needs

Beyond superior machine performance, Sanyhore offers more than just equipment. As a professional manufacturer specializing in hinge assembly machines, telescopic drawer slide assembly machines, and roll forming machines, we understand the unique challenges of slide production. Our team provides personalized support, including on-site installation, operator training, and after-sales service to maximize machine uptime. We prioritize long-term partnerships, offering competitive pricing and flexible customization options to meet your production goals. Whether you’re scaling up production or upgrading existing equipment, Sanyhore delivers reliable solutions tailored to your requirements.

Contact Us to Explore Our Fast-Speed Drawer Slide Roll Forming Machines

Ready to enhance your drawer slide production efficiency? Get in touch with Sanyhore today. Our sales team is available to discuss your specific needs, provide detailed technical specifications, and arrange a factory tour. For inquiries, reach us at +86 13425506550 or send an email to info@sanyhore.com. Let’s build a stronger partnership to drive your manufacturing success.

Common SEO Questions for Drawer Slide Manufacturing

1. Q: What makes a roll forming machine suitable for high-speed drawer slide production?

A: Fast-Speed Drawer Slide Roll Forming Machines combine high-torque servo drives, optimized roll tooling, and automated material handling to achieve continuous, high-volume production with minimal downtime.

2. Q: How does Sanyhore ensure the precision of its drawer slide roll forming machines?

A: Our machines use precision CNC-machined dies, real-time feedback sensors, and strict quality checks to maintain tight tolerances, ensuring consistent slide dimensions and performance.

3. Q: Can your roll forming machine produce custom drawer slide profiles?

A: Yes, with modular tooling systems and quick-change die sets, we can adapt to various slide designs, including telescopic, side-mount, and under-mount configurations.

4. Q: What after-sales support does Sanyhore provide for its roll forming machines?

A: We offer comprehensive after-sales service including installation guidance, operator training, and 24/7 technical support to ensure your machine operates at peak efficiency.

5. Q: How does Sanyhore’s production capacity meet large-scale drawer slide orders?

A: With a monthly capacity of 50,000+ drawer slide rails and a dedicated team, we efficiently handle both standard and large-batch production requirements.