The manufacturing industry stands at a critical inflection point, where the line between conventional and cutting-edge production is blurring rapidly. Traditional manufacturing, rooted in manual labor, standardized processes, and limited data integration, has long been the backbone of industrial output. However, today’s market demands—for faster turnaround, greater customization, and enhanced sustainability—are forcing a fundamental shift. This transition, from traditional to transformational manufacturing, is not merely an upgrade but a complete reimagining of how products are designed, produced, and delivered. It hinges on integrating advanced technologies, fostering data-driven decision-making, and prioritizing adaptability. For businesses aiming to stay relevant, this shift is no longer optional; it’s a necessity.

The Limitations of Traditional Manufacturing

Traditional manufacturing often operates within rigid frameworks. Production lines rely heavily on manual labor, leading to inconsistencies in quality and output. Workers, despite their skill, are prone to human error, especially in repetitive tasks like assembling components. This not only increases defect rates but also extends production cycles, making it hard to meet tight deadlines. Additionally, traditional systems lack real-time data visibility. Managers depend on post-shift reports, which means issues are identified too late to prevent delays or losses. Inventory management is another challenge—excess stock ties up capital, while stockouts disrupt operations. In an era where consumers expect personalized products, traditional batch-and-queue methods struggle to scale, limiting growth potential.

The Catalysts Driving Transformational Shift

Several forces are propelling the shift to transformational manufacturing. Global competition has intensified, with players worldwide vying for market share, driving the need for operational efficiency. Consumer expectations have evolved too; today’s buyers demand tailored products, shorter lead times, and transparent supply chains. Technological advancements, particularly in automation, AI, and IoT, have made transformation feasible and affordable. For instance, the rise of Industry 4.0 has introduced smart factories where machines communicate, data is collected in real time, and decisions are optimized. Sustainability is another key driver—governments and consumers increasingly prioritize eco-friendly production, pushing manufacturers to reduce waste and energy consumption. Together, these factors create a compelling case for change.

Key Technologies Powering the Transformation

At the heart of transformational manufacturing lies a suite of technologies that redefine production. Automation, in the form of collaborative robots (cobots) and automated machinery, handles repetitive tasks with precision, reducing human error and freeing workers for creative or complex roles. Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) systems streamline product development, enabling faster prototyping and iteration. Data analytics and the Internet of Things (IoT) connect machines to central systems, allowing predictive maintenance, real-time quality checks, and performance tracking. AI further enhances this by analyzing data to identify bottlenecks, optimize workflows, and even predict demand. These technologies collectively turn manufacturing from a linear process into a dynamic, interconnected ecosystem.

Benefits of Embracing Transformational Manufacturing

The rewards of this shift are substantial. For starters, efficiency soars. Automated assembly lines reduce production time by up to 50% compared to manual operations, while data-driven insights cut waste by minimizing defects and rework. Customization becomes manageable, as flexible systems can adapt to small-batch or one-off orders without significant setup costs. Agility improves too—factories can quickly adjust to market changes, whether scaling up for peak demand or pivoting to new product lines. Quality control becomes proactive, not reactive, with real-time monitoring catching issues before they impact output. Over time, these improvements translate to lower costs, higher customer satisfaction, and a stronger competitive edge in the global market.

Sanyhore: Your Partner in Manufacturing Evolution

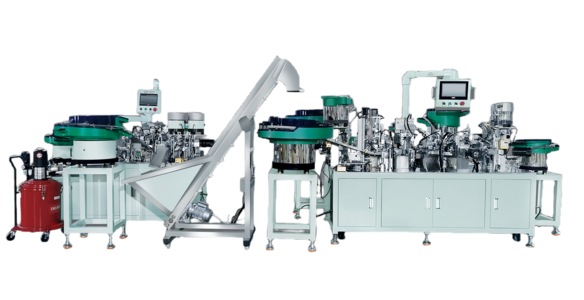

To successfully navigate this transition, manufacturers need reliable, innovative equipment that integrates seamlessly into their operations. Sanyhore, a trusted name in manufacturing solutions, specializes in creating cutting-edge machinery tailored for transformation. Our range includes advanced hinge assembly machines, engineered to automate component joining with precision and consistency, reducing manual effort by 60% and boosting throughput by 40%. For those in the furniture or automotive sectors, our telescopic drawer slide assembly machines combine high-speed production with adaptive control systems, ensuring every slide meets exacting standards. Additionally, our roll forming machines offer efficient, continuous production of metal components, ideal for scaling up operations while maintaining quality.

At Sanyhore, we understand that transformation is a journey, not a destination. That’s why we work closely with clients to design solutions that align with their unique goals, whether upgrading existing lines or building new smart factories. Our commitment to innovation means our machines are built with the latest technologies—AI-driven diagnostics, IoT connectivity, and modular designs—ensuring long-term reliability and adaptability. Ready to leave traditional manufacturing behind and embrace the future? Contact us today at +86 13425506550 or via email at info@sanyhore.com to discuss how we can help your business evolve. The future of manufacturing is transformational—let’s build it together.