Introduction

In the global landscape of precision manufacturing, Jieyang, a city in Guangdong Province, China, has emerged as a pivotal hub for advanced assembly solutions. Renowned for its cluster of manufacturing enterprises, Jieyang has particularly excelled in one niche: 3D hinge assembly machine technology. As demand for thinner, more flexible, and multi-functional devices—from smartphones to IoT gadgets—soars, the need for 3D hinge systems, which enable rotational movement in three axes with minimal play, has surged. Local factories in Jieyang have not only met this demand but have also redefined industry standards by integrating cutting-edge automation, AI-driven precision, and lean production practices. This article explores how Jieyang factories have become leaders in 3D hinge assembly machine technology, driving innovation and setting benchmarks for the global manufacturing sector.

Technological R&D: The Backbone of 3D Hinge Assembly Mastery

At the core of Jieyang’s success lies a relentless focus on research and development (R&D). Unlike many regions where assembly machine technology is often imported or adapted, local factories have invested heavily in in-house innovation. A key driver is their ability to collaborate with local engineering institutes, creating a synergy between academic research and real-world production needs. For instance, factories have developed proprietary 3D coordinate system calibration algorithms, enabling assembly machines to achieve sub-micron precision in aligning hinge components. This precision is critical, as even a 0.01mm misalignment can lead to premature hinge failure or inconsistent performance, which is unacceptable in high-end consumer electronics.

Additionally, Jieyang manufacturers have pioneered modular mechanical design for 3D hinge assembly machines. Traditional machines often required lengthy retooling for different hinge models, but modern systems from local factories use interchangeable tooling and adaptive grippers, reducing setup time by up to 60%. This modularity not only boosts efficiency but also allows factories to quickly scale production for new hinge designs, a critical advantage in fast-paced consumer markets.

Streamlining Production: Balancing Speed, Accuracy, and Scalability

Efficiency is another hallmark of Jieyang’s 3D hinge assembly machines. Factories here have embraced Industry 4.0 principles, integrating IoT sensors, real-time data analytics, and machine learning to optimize every stage of production. For example, AI-powered predictive maintenance systems monitor machine health, alerting operators to potential issues before breakdowns occur, minimizing downtime. Quality control is also seamlessly integrated into the production line: in-line vision inspection systems, equipped with high-speed cameras and deep learning models, check hinge component tolerances, backlash, and rotational smoothness in under 0.5 seconds per unit.

Moreover, Jieyang factories prioritize energy-efficient manufacturing. By using servo-driven systems and lightweight materials in machine construction, they have reduced energy consumption by 30% compared to older models, aligning with global sustainability goals. This focus on both performance and resource optimization has made their machines highly attractive to international buyers seeking cost-effective yet eco-friendly solutions.

Adapting to Diverse Industry Needs: From Consumer Tech to Industrial Applications

While 3D hinge assembly machines in Jieyang initially catered to consumer electronics, their versatility has expanded to industrial sectors, including automotive, medical devices, and aerospace. For instance, automotive manufacturers now use these machines to assemble door hinges with 3D rotational precision, ensuring smooth operation and durability. Medical device companies rely on their ability to create micro-hinges for surgical tools, where precision and sterility are non-negotiable.

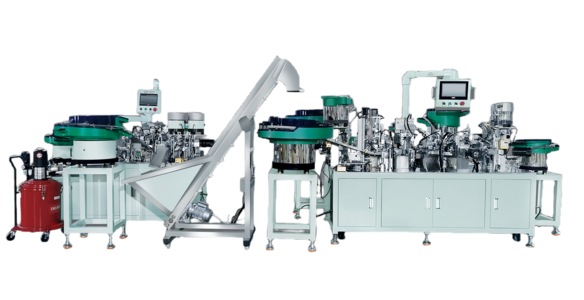

Local factories excel at customizing machines to meet unique client requirements. Sanyhore, a leading manufacturer in Jieyang, for example, offers 3D hinge assembly systems tailored to produce hinges with specific torque ranges, load capacities, and size constraints. This flexibility is a result of close collaboration with clients during the design phase, where engineers from both sides co-develop solutions that balance performance, cost, and production volume.

The Role of Sanyhore: A Trusted Partner in Hinge Assembly Innovation

As a key player in Jieyang’s manufacturing ecosystem, Sanyhore embodies the city’s commitment to excellence in 3D hinge assembly machine technology. The company specializes in developing and producing a comprehensive range of solutions, including 3D hinge assembly machines, telescopic drawer slide assembly machines, and roll forming machines for滑轨 (sliding rails) used in furniture and industrial equipment. By leveraging the city’s R&D strengths and production capabilities, Sanyhore has built a reputation for reliability, with its machines deployed across major markets in Europe, Southeast Asia, and North America.

What sets Sanyhore apart is its dedication to long-term client success. Beyond machine supply, the company offers technical support, spare parts, and on-site training to ensure seamless integration into clients’ production lines. For businesses looking to adopt 3D hinge assembly technology or upgrade existing systems, partnering with a local expert like Sanyhore ensures access to cutting-edge solutions without the complexities of international supply chains.

Conclusion

Jieyang’s factories have not just kept pace with global demands for 3D hinge assembly machine technology—they have set new standards. Through relentless R&D, optimized production processes, and a client-centric approach, these manufacturers have transformed the industry, making 3D hinge assembly machines more precise, efficient, and adaptable than ever before. For companies aiming to enhance their production capabilities, reaching out to local leaders like Sanyhore is the first step toward unlocking the full potential of modern hinge assembly solutions.

To discuss your specific needs, contact Sanyhore’s sales manager at +86 13425506550 or send an email to info@sanyhore.com. Let us help you build a more robust, efficient, and innovative manufacturing process with advanced 3D hinge assembly technology.