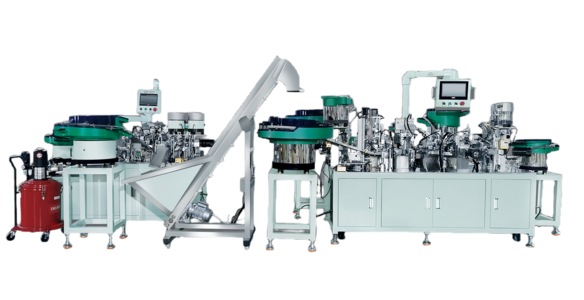

In modern manufacturing, human-machine collaboration (HMC) has evolved from a trend to a necessity, especially in precision industries like hinge production. This article delves into the human-machine collaboration process for Jieyang hinge automatic assembly machines, exploring how human expertise and machine precision converge to redefine production efficiency, quality control, and operational flexibility. As a leading manufacturer of hinge assembly equipment, Sanyhore integrates this collaborative model into its machines, ensuring seamless interaction between operators and automated systems.

Introduction to Human-Machine Collaboration in Hinge Assembly

Human-machine collaboration in hinge assembly refers to a symbiotic workflow where humans and machines each contribute their unique strengths. Unlike fully automated systems that replace human involvement, HMC retains human oversight, creativity, and adaptability while leveraging machines' precision, speed, and consistency. For hinge assembly, this means operators handle tasks requiring judgment, problem-solving, and initial setup, while machines execute repetitive, high-precision steps like component alignment, welding, and press-fitting. This balance not only boosts productivity but also reduces the risk of errors and physical strain on workers.

Core Components of the Hinge Assembly Collaboration System

A robust human-machine collaboration system for hinge assembly relies on three key components: advanced automation hardware, intuitive human-machine interface (HMI), and real-time data integration. The automation hardware includes collaborative robots (cobots) with force-limiting technology, high-precision grippers, and vision systems that inspect components for defects. The HMI, typically a touchscreen panel, allows operators to input parameters, monitor machine status, and adjust workflows. Real-time data integration ensures operators receive instant feedback on production metrics, such as assembly speed, component accuracy, and machine performance, enabling proactive adjustments.

Step-by-Step Process of Human-Machine Collaboration

The human-machine collaboration process for Jieyang hinge automatic assembly machines follows a structured sequence, ensuring clarity and efficiency:

1. Pre-Operation Setup: Before production, the operator loads raw hinge components (e.g., leaves, pins, bushings) into designated inlets. Using the HMI, they input production parameters, such as target speed and component tolerances, based on product specifications.

2. Machine Initialization: The system powers up, with cobots and vision systems calibrating to reference points. Sensors check for component presence and correct orientation, ensuring readiness for assembly.

3. Human-Machine Coordination: The operator performs a quick visual inspection of the first few components, verifying alignment and fit. If adjustments are needed (e.g., misaligned parts), they use the HMI to tweak machine parameters, such as gripper pressure or robotic movement speed.

4. Automated Assembly Execution: The cobot then takes over, executing precise steps: picking components from feeders, aligning them with vision guidance, and joining them using ultrasonic welding or press-fitting. The machine’s speed—often 10-20 cycles per minute—far exceeds manual assembly, reducing cycle time by 60% or more.

5. Quality Control and Feedback: After assembly, the vision system inspects each hinge for critical dimensions (e.g., pin depth, leaf alignment) and functionality (e.g., opening/closing resistance). If a defect is detected, the system pauses, and the operator is notified via visual and audio alerts. The operator then removes the defective unit, and the system resumes production after adjustment.

6. Data Logging and Optimization: Throughout the process, data on production volume, defect rates, and machine runtime is logged. Operators and engineers use this data to identify bottlenecks, refine workflows, and enhance overall system performance over time.

Benefits of Implementing Human-Machine Collaboration

The human-machine collaboration model offers tangible benefits for hinge assembly operations:

- Enhanced Productivity: By offloading repetitive tasks to machines, operators focus on high-value activities, increasing overall production output by up to 40%.

- Improved Quality: Machine precision minimizes errors from human fatigue or inconsistency, reducing defect rates to less than 0.5%.

- Reduced Labor Intensity: Operators avoid repetitive motion injuries, and the system’s user-friendly interface lowers training requirements.

- Flexible Production: The modular design of the collaboration system allows quick reconfiguration for different hinge models, adapting to changing market demands.

Technical Considerations for Seamless Integration

To ensure smooth human-machine collaboration, several technical factors must be addressed:

- Safety Compliance: The system adheres to international safety standards (e.g., ISO/TS 15066 for collaborative robots), with force sensors that stop operations if human contact is detected.

- HMI Usability: The interface is designed with large, clear icons, customizable workflows, and real-time diagnostics to minimize operator learning curves.

- Data Security: Production data is encrypted and transmitted securely, preventing unauthorized access and ensuring compliance with data privacy regulations.

- Maintainability: Components like grippers and sensors are modular, allowing quick replacement to reduce downtime, with predictive maintenance alerts to prevent unexpected failures.

Conclusion and Call to Action

Human-machine collaboration has transformed hinge assembly, merging human judgment with machine precision to create efficient, reliable, and flexible production systems. For manufacturers looking to upgrade their operations, Sanyhore offers cutting-edge hinge automatic assembly machines designed with this collaborative model in mind. As a professional producer of hinge assembly machines, telescopic drawer slide assembly machines, and roll forming machines, Sanyhore provides tailored solutions to meet diverse production needs.

Ready to enhance your hinge assembly efficiency? Contact Sanyhore today to discuss your requirements. Our team of experts is available to provide detailed insights and support. Reach us at +86 13425506550 or via email at info@sanyhore.com.