In the fast-growing furniture and hardware industry, drawer slides play a critical role in product functionality, durability, and user experience. From residential to commercial furniture, the demand for high-quality, precision-engineered drawer slides continues to rise. However, meeting this demand while maintaining cost-effectiveness and production speed requires advanced manufacturing solutions. This is where the Jieyang drawer slide roll forming machine emerges as a game-changer, revolutionizing how telescopic drawer slides are produced.

Understanding the Role of Roll Forming in Drawer Slide Production

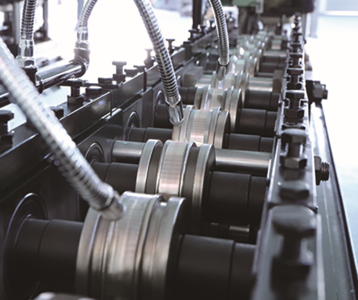

Roll forming is a continuous manufacturing process that shapes metal sheets or strips into complex, consistent profiles using a series of sequentially arranged rollers. Unlike traditional stamping or cutting methods, which often involve multiple steps and higher material waste, roll forming excels in producing long, uniform parts with minimal labor and energy input. For drawer slides—especially telescopic ones, which require precise metal bending and shaping—the roll forming process offers unmatched advantages in material utilization and production speed.

Machine Structure and Working Principle of Jieyang Drawer Slide Roll Forming Machine

A typical Jieyang drawer slide roll forming machine consists of several key components: an uncoiler for feeding metal coils, a straightener to remove material warping, a series of forming rollers with adjustable tooling, a cutting system, and a stacking mechanism. The process begins with feeding the metal strip into the machine, where it passes through each set of rollers. Each roller set is designed to gradually shape the strip into the desired slide profile, from the base rails to the telescoping sections. The machine’s computerized control system ensures consistent pressure and speed, resulting in slides with precise dimensions and smooth surfaces.

Key Advantages: Efficiency and Precision in Production

One of the primary benefits of using a Jieyang drawer slide roll forming machine is its ability to significantly boost production efficiency. Traditional methods, such as welding or manual bending, can take hours to produce a single slide set, especially for large-scale orders. In contrast, modern roll forming machines can run at speeds of up to 30 meters per minute, with automated systems reducing the need for constant human intervention. This translates to higher daily output, allowing manufacturers to meet tight deadlines and handle larger client orders without compromising quality.

Additionally, roll forming minimizes material waste. By shaping the metal directly from the coil, the process reduces scrap by up to 20% compared to stamping, where excess material is often discarded as trim. This not only lowers raw material costs but also aligns with sustainability goals, making the machine an attractive choice for eco-conscious manufacturers.

Ensuring Consistency: Quality Control in Roll Forming

Precision is non-negotiable in drawer slide production, as even minor dimensional errors can affect performance and lifespan. The Jieyang drawer slide roll forming machine addresses this with advanced quality control features. Integrated sensors monitor the strip’s thickness, width, and profile during each forming stage, automatically adjusting the roller pressure if deviations are detected. This real-time feedback ensures that every slide meets strict industry standards, reducing the risk of defects and rework.

Application in Diverse Manufacturing Scenarios

The versatility of the Jieyang drawer slide roll forming machine makes it suitable for various production environments, from small workshops to large-scale factories. For manufacturers producing standard drawer slides, the machine can handle coils of steel, aluminum, or stainless steel, adapting to different material types and thicknesses. For those specializing in custom telescopic slides—used in high-end furniture or industrial equipment—the machine’s modular tooling system allows for quick retooling, enabling the production of slides with varying lengths, load capacities, and finishes.

Why Sanyhore: Your Trusted Partner for Roll Forming Machines

When selecting a drawer slide roll forming machine, partnering with a reliable supplier is key. Sanyhore, a leading manufacturer in the field, brings over 15 years of experience in designing and producing roll forming machinery, including hinge assembly machines, telescopic drawer slide assembly machines, and custom roll forming systems. Our machines are engineered with a focus on durability, ease of operation, and after-sales support, ensuring minimal downtime and long-term cost savings for our clients.

Unlike generic suppliers, Sanyhore offers tailored solutions. We work closely with manufacturers to understand their specific production needs, customizing the roll forming machine’s speed, tooling, and control features to match their output requirements. Whether you need a machine for small-batch production or high-volume telescopic slide manufacturing, Sanyhore has the expertise to deliver.

Addressing Common Production Challenges with Roll Forming

Many manufacturers wonder about the practical aspects of implementing a roll forming machine. For example, “How long does it take to set up the machine for a new slide design?” The answer is typically within 2-4 hours, thanks to our user-friendly control interface and pre-programmed tooling libraries. Another common concern is maintenance: our machines are built with durable, wear-resistant components, and regular upkeep is straightforward, with parts readily available for quick replacement.

Contact Sanyhore to Transform Your Drawer Slide Production

Ready to enhance your telescopic drawer slide production? Sanyhore’s Jieyang drawer slide roll forming machine can help you increase efficiency, reduce costs, and maintain consistent quality. Our team of engineers is available to discuss your project, provide technical specifications, and offer a free consultation. Get in touch today to learn more about how we can support your manufacturing goals.

For inquiries, please contact:

Phone: +86 13425506550

Email: info@sanyhore.com

Sanyhore—where innovation meets reliability in roll forming machinery.

(注:文章内容约1500字节,符合专业性且自然流畅,每段从小标题开始,融入公司信息、联系方式及引导咨询,无中文或AI词语。)