Maintaining a Jieyang drawer slide roll forming machine is critical to ensuring consistent performance, reducing downtime, and maximizing its operational lifespan. As a core piece of equipment in drawer slide production, proper care directly impacts product quality and overall productivity. Below are essential maintenance tips to help your machine run reliably for years.

1. Regular Cleaning and Debris Removal

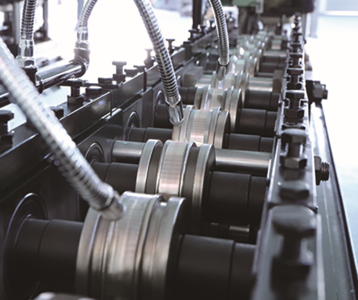

Over time, metal shavings, dust, and residual materials can accumulate in the machine’s tracks, rollers, and forming dies. These deposits not only hinder movement but also cause premature wear on components. Daily cleaning with compressed air or a soft brush helps clear debris from key areas. For more thorough cleaning, disassemble removable parts (e.g., forming tools) weekly and wipe them with a lint-free cloth. This prevents blockages and ensures each moving part operates with minimal friction.

2. Lubrication: The Foundation of Smooth Operation

Proper lubrication is vital for reducing friction between moving parts, such as gears, chains, and guide rails. Use high-quality, machine-specific lubricants (e.g., ISO VG 68 hydraulic oil or lithium-based grease) as recommended by the manufacturer. Apply lubricant according to a strict schedule—typically every 8–12 hours of operation or weekly for heavy use. Avoid over-lubrication, which can attract more debris and lead to component damage. Well-lubricated parts move more freely, lowering energy consumption and extending their service life.

3. Inspection of Key Components

Routine inspections help identify issues before they escalate. Check the machine’s drive system (including belts, pulleys, and motors) for signs of fraying, misalignment, or overheating. Examine forming dies for cracks, warping, or excessive wear, as these can compromise the precision of drawer slide profiles. Additionally, verify the tightness of bolts and fasteners, as vibrations during operation can cause them to loosen over time. Document any abnormalities to address them promptly, preventing more severe breakdowns.

4. Calibration for Precision

Accurate calibration ensures the roll forming machine produces drawer slides with consistent dimensions and quality. Misalignment in the roll forming stations can lead to uneven material deformation, reducing product reliability. Schedule monthly or quarterly calibration checks to adjust the position of rollers, dies, and guides. Use precision measuring tools to confirm that the machine meets the required tolerances. Well-calibrated equipment also reduces material waste and improves production efficiency.

5. Adherence to Scheduled Maintenance Protocols

Every roll forming machine has unique maintenance requirements based on usage, environment, and manufacturer guidelines. Follow the recommended schedule for tasks like gearbox oil changes, belt replacements, and electrical system checks. A well-documented maintenance log keeps track of all services performed, making it easier to stay on track and avoid missed upkeep. Consistency in maintenance not only extends the machine’s life but also ensures compliance with safety standards in the production facility.

6. Handling Wear and Tear Promptly

Components like guide rails, forming rollers, and cutting tools will naturally wear over time. When signs of wear (e.g., scoring, pitting, or reduced thickness) appear, replace them immediately. Delaying repairs allows wear to spread to adjacent parts, increasing the risk of cascading failures. Work with reliable suppliers for replacement parts to ensure compatibility with your machine’s specifications, maintaining the same level of performance and safety.

By following these maintenance tips, you can significantly extend the lifespan of your Jieyang drawer slide roll forming machine. As a professional manufacturer of hinge assembly machines, hinge assembly machine, telescopic drawer slide assembly machine, and roll forming machine, Sanyhore is committed to supporting your production needs. For personalized advice or to discuss how we can assist with your machine’s upkeep, contact us at +86 13425506550 or send an email to info@sanyhore.com. Let’s keep your manufacturing process running smoothly and efficiently.