Introduction to Jieyang Drawer Slide roll forming machines

In the cabinet manufacturing industry, drawer slides are more than just functional components—they directly influence product quality, user satisfaction, and production costs. As a critical part of furniture assembly, drawer slides must meet strict standards for durability, smooth operation, and dimensional accuracy. This is where Jieyang drawer slide roll forming machines (DRFM) play a pivotal role. Designed specifically for cabinet making, these machines combine advanced roll forming technology with industry-specific requirements to produce high-quality telescopic drawer slides efficiently. Whether for small-scale workshops or large production lines, DRFM from reliable manufacturers like Sanyhore are reshaping how cabinet makers approach slide production, balancing precision, speed, and cost-effectiveness.

Key Advantages for Cabinet Makers

For cabinet manufacturers, the right equipment can streamline operations and enhance product competitiveness. Jieyang drawer slide roll forming machines offer several key advantages that align with the demands of cabinet making:

- High Precision: The roll forming process ensures consistent dimensions, with tight tolerances (often within 0.1mm) that prevent issues like misalignment or stuck slides. This precision is critical for cabinet slides, which need to glide smoothly over thousands of uses.

- Efficiency: Unlike traditional manufacturing methods, roll forming allows for continuous production, reducing cycle times and increasing output. Cabinet makers can meet tight order deadlines without compromising quality.

- Material Optimization: Roll forming minimizes material waste by using coiled steel and shaping it directly into the slide profile, unlike cutting or stamping, which often result in scrap. This lowers raw material costs, a significant benefit for manufacturers.

- Flexibility: Modern DRFM models support quick die changes, enabling production of various slide sizes and styles to adapt to diverse cabinet designs—from compact kitchen units to large furniture pieces.

Technical Features of the Roll Forming Process

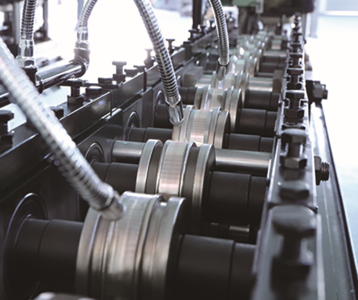

The core of Jieyang drawer slide roll forming machines lies in their roll forming technology, a process that transforms flat metal sheets into complex, precise profiles through a series of consecutive rolling passes. Key technical features include:

- Multi-Station Roll Forming: The machine incorporates multiple sets of precision rollers arranged in a sequence, each shaping the metal to form the slide’s rail, track, and other components. This step-by-step approach ensures each part of the slide meets exact specifications.

- Automated Control System: Equipped with advanced PLC controls, the DRFM integrates automated feeding, positioning, and cutting systems. Sensors monitor the process in real time, adjusting parameters like speed or pressure to maintain consistency.

- Customizable Die Sets: Manufacturers can swap out die sets to produce different slide profiles, such as single-extension, double-extension, or telescopic designs—common in cabinet applications. This adaptability is key for meeting varied client demands.

- High-Speed Production: With an operational speed ranging from 10 to 30 meters per minute (depending on model), these machines can handle large production volumes, making them ideal for cabinet makers scaling up their operations.

Enhancing Production Efficiency in Cabinet Manufacturing

In cabinet making, efficiency is often the difference between profitability and operational strain. Jieyang drawer slide roll forming machines directly address this by:

- Reducing Manual Labor: Automated processes minimize the need for manual material handling and assembly, freeing workers to focus on more complex tasks like cabinet finishing or quality inspection.

- Eliminating Production Bottlenecks: Unlike manual or semi-automatic methods that may slow down at key stages (e.g., cutting or welding), roll forming ensures a steady, continuous flow from raw material to finished slide, reducing downtime between production runs.

- Scaling with Demand: By optimizing for high-volume production, DRFM allows cabinet manufacturers to ramp up output quickly during peak seasons, such as before major shopping events, without sacrificing slide quality.

Quality Control and Durability: Ensuring Long-Lasting Drawer Slides

For cabinet slides, durability is non-negotiable—they need to withstand repeated use, weight, and environmental factors like humidity. Jieyang drawer slide roll forming machines integrate quality control measures to ensure slides meet these standards:

- Material Selection: The machines are compatible with high-grade steel (e.g., cold-rolled steel or stainless steel) to ensure slides resist wear and corrosion, critical for long-term cabinet performance.

- In-Process Monitoring: Advanced DRFM models include inline inspection tools, such as laser measuring systems, to check dimensions during production, catching deviations early to prevent defective slides.

- Post-Forming Processes: Many manufacturers pair DRFM with secondary operations like punching, bending, or polishing, ensuring slides are not only dimensionally accurate but also visually and functionally flawless.

Why Choose Sanyhore for Your Roll Forming Needs

When selecting a drawer slide roll forming machine, working with a trusted manufacturer is essential to ensure reliability and after-sales support. Sanyhore, a professional producer of cabinet making machinery, has built its reputation on delivering high-performance roll forming machines tailored to industry needs. As a leading manufacturer of hinge assembly machines, telescopic drawer slide assembly machines, and roll forming machines, Sanyhore combines technical expertise with a customer-centric approach to meet the unique requirements of cabinet makers.

At Sanyhore, we understand that every cabinet production line is different. That’s why we offer customizable DRFM models, from entry-level machines for small workshops to fully automated systems for large-scale manufacturers. Our machines are designed to boost production efficiency, reduce costs, and ensure the consistent quality that cabinet brands demand. With a focus on innovation and durability, Sanyhore’s roll forming machines have become a preferred choice for cabinet makers worldwide.

Contact Us to Elevate Your Cabinet Manufacturing

Ready to upgrade your cabinet making process with a reliable drawer slide roll forming machine? Sanyhore is here to help. As a dedicated manufacturer of high-quality cabinet machinery, we’re committed to providing solutions that drive efficiency and quality in your production line.

For more information about our Jieyang drawer slide roll forming machines or to discuss your specific cabinet making needs, reach out to our team today. Call us at +86 13425506550 or send an email to info@sanyhore.com to request a quote or schedule a consultation. Let’s build a more efficient, productive cabinet manufacturing workflow together.