Jieyang drawer slide roll forming machines play a critical role in the efficient production of high-quality telescopic drawer slides, widely used in furniture, automotive, and storage industries. However, even with robust equipment, operators often encounter operational issues that affect productivity and product quality. This guide explores common troubleshooting solutions for Jieyang drawer slide roll forming machines, helping manufacturers minimize downtime and ensure consistent output.

Material-Related Defects

Material inconsistencies are among the most frequent issues in roll forming. For example, uneven material thickness or surface scratches can lead to uneven slide dimensions or surface damage. This often stems from poor material quality or improper feeding mechanisms. To address this, operators should first inspect incoming materials for defects, ensuring they meet specified tolerances. Additionally, adjusting the feed roller pressure and installing a material guide system can stabilize feeding, reducing misalignment. Regularly cleaning the feed table to remove debris also prevents material jams and scratches.

Parameter Misalignment

Incorrect parameter settings, such as roll forming speed, pressure, or roll gap, directly impact product precision. A common scenario is excessive speed causing material stretching, while insufficient pressure may lead to incomplete forming. To resolve this, refer to the machine’s operation manual for recommended parameters based on material type and slide design. Modern roll forming machines often include automated control systems that adjust parameters in real time, but manual calibration may be needed for complex slide profiles. Periodically testing sample products and fine-tuning parameters ensures the machine operates within optimal ranges.

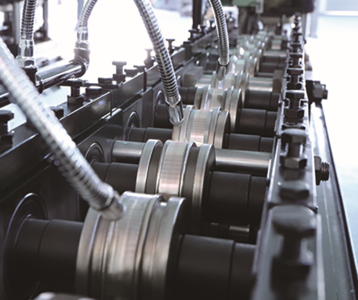

Tooling and Die Issues

Worn or misaligned tools and dies are another key troubleshooting area. Over time, dies can wear down, leading to burrs or incomplete notches in the slide rails. Misalignment of the die set can cause lateral shifts, resulting in uneven flanges. Regular inspection of die components—including checking for cracks, wear patterns, and tightness—is essential. Replacing worn dies promptly and adjusting die alignment using precision measuring tools (e.g., dial indicators) helps maintain consistent product quality. For long-term durability, storing unused dies in a controlled environment prevents premature degradation.

Operational Process Errors

Human error during setup or operation can also disrupt production. For instance, incorrect tool positioning or failure to lock the machine’s safety interlocks may lead to unexpected stops or part defects. Implementing standardized operating procedures (SOPs) and training operators to follow step-by-step protocols minimizes such errors. Using visual aids, such as color-coded labels for critical settings, can further reduce miscommunication. Additionally, integrating emergency stop systems and regular operator drills ensures quick response to anomalies, preventing equipment damage and production delays.

Maintenance and Longevity

Neglecting regular maintenance is a hidden cause of recurring issues. Insufficient lubrication of moving parts, such as gears and bearings, leads to increased friction and wear. Over time, this can cause abnormal noise, vibration, or even component failure. Establishing a maintenance schedule that includes daily, weekly, and monthly checks—such as lubricating key parts, tightening loose fasteners, and inspecting belts and chains—extends the machine’s lifespan. For complex components like the roll forming system, partnering with a reliable manufacturer for periodic overhauls ensures optimal performance.

When facing persistent issues with your Jieyang drawer slide roll forming machine, remember Sanyhore—a professional manufacturer specializing in the production of telescopic drawer slide assembly machines, hinge assembly machines, and high-quality roll forming machines. With years of expertise in manufacturing equipment, we offer technical support and solutions tailored to your production needs. Contact us today at +86 13425506550 or via email at info@sanyhore.com to discuss your machine troubleshooting requirements.