In the dynamic world of manufacturing, the demand for high-quality, cost-effective drawer slides has surged with the growth of furniture, automotive, and storage industries. Central to meeting this demand is the roll forming machine, a critical piece of equipment that shapes metal strips into precise, consistent drawer slide components. Among the leading manufacturers of such machines is Jieyang, a hub of innovation in roll forming technology, with its drawer slide roll forming machines standing out for their performance, reliability, and adaptability to diverse production needs.

Understanding Roll Forming Technology for Drawer Slides

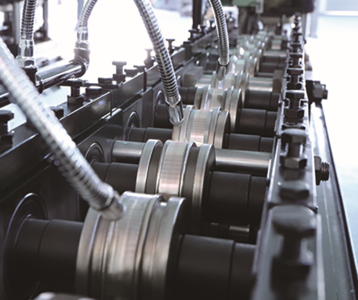

Roll forming is a continuous shaping process where flat metal coils are progressively formed into complex cross-sections through a series of rotating dies. Unlike stamping or welding, which require multiple steps, roll forming streamlines production by integrating material feeding, shaping, and cutting into a single, continuous operation. For drawer slides, this method is ideal because it ensures uniform thickness, tight tolerances, and minimal material waste—key factors in producing slides that function smoothly and last longer. Jieyang’s machines leverage this technology to create slides with consistent dimensions, a critical advantage for manufacturers aiming to meet strict industry standards.

Key Advantages of Jieyang’s Drawer Slide Roll Forming Machine

Jieyang’s drawer slide roll forming machines excel in several areas that set them apart from competitors. First, they offer exceptional production speed, with some models capable of running at 10-15 meters per minute, significantly increasing output for large-scale orders. Second, the machines feature advanced computer numerical control (CNC) systems, allowing operators to precisely adjust parameters like roll gap, speed, and material tension to match specific slide designs. This precision reduces errors and rework, cutting production costs over time. Additionally, Jieyang machines are engineered with modular components, enabling easy maintenance and quick tool changes, minimizing downtime during production transitions.

Enhanced Production Efficiency Through Advanced Engineering

Modern manufacturing requires more than just producing parts—it demands efficiency. Jieyang’s roll forming machines address this by integrating automated material handling systems, such as coil uncoilers with hydraulic tension control and in-line straightening units. These features eliminate manual intervention, reduce operator fatigue, and ensure a steady supply of material to the forming dies. Furthermore, the machines are equipped with integrated cutting systems, often using flying saw or shear mechanisms, to cut slides to exact lengths without stopping the production line. This continuous operation not only boosts output but also maintains consistent quality throughout the run.

Precision and Consistency: Critical for High-Quality Drawer Slides

Drawer slides rely on tight tolerances to ensure smooth movement and longevity. A single deviation in dimensions can lead to jamming, premature wear, or failure, affecting both product performance and customer satisfaction. Jieyang’s roll forming machines mitigate this risk through high-precision roll tooling, made from hardened steel alloys that maintain their shape even after thousands of hours of use. The machines also include feedback systems, such as laser sensors or vision systems, to monitor the forming process in real time, adjusting for any minor variations in material thickness or feed speed. This level of control ensures that every slide produced meets the required specifications, from the smallest residential slide to heavy-duty industrial variants.

Durability and Longevity: Built for Heavy Industrial Use

In industrial settings, equipment must withstand continuous operation, heavy loads, and exposure to various environmental conditions. Jieyang addresses this by constructing its roll forming machines with robust materials and a focus on structural integrity. The frame is typically made from cast iron or heavy-duty steel, providing a stable base that minimizes vibration and ensures consistent performance over years of use. The drive systems, including high-torque motors and precision gearboxes, are designed to handle the mechanical stress of processing thick or hard metals, reducing the need for frequent repairs. Combined with regular maintenance, these machines offer a long service life, making them a cost-effective investment for manufacturers prioritizing reliability.

Why Choose a Local Manufacturer: The Jieyang Advantage

While global suppliers offer roll forming machines, Jieyang’s local presence provides unique benefits for manufacturers. Proximity allows for faster communication, on-site technical support, and quick delivery of replacement parts, reducing production disruptions. Local manufacturers also have a deep understanding of regional production needs, such as material availability and industry-specific standards, enabling them to tailor machines to local requirements. For example, Jieyang’s machines are often optimized to work with common steel grades used in drawer slide production, ensuring compatibility and seamless integration into existing production lines.

Partnering with Sanyhore: Your Trusted Roll Forming Machine Supplier

For over a decade, Sanyhore has specialized in developing and manufacturing high-performance roll forming machines, including hinge assembly machines, telescopic drawer slide assembly machines, and the advanced roll forming systems for drawer slide production. As a trusted partner to manufacturers worldwide, we understand the unique demands of producing drawer slides that meet strict industry standards for durability and functionality. Our team of engineers works closely with clients to design solutions that align with their production goals, whether scaling up output, improving product quality, or reducing operational costs.

To learn more about how a Jieyang drawer slide roll forming machine can transform your production line, contact Sanyhore today. Our team of experts is ready to discuss your specific needs and provide tailored solutions. Reach out via phone at +86 13425506550 or email at info@sanyhore.com to schedule a consultation.