Jieyang’s 3D hinge assembly technology innovations are reshaping modern manufacturing, blending cutting-edge engineering with practical production needs. As a hub for precision manufacturing, local factories here are leading advancements in 3D hinge assembly, addressing longstanding challenges in component alignment, material compatibility, and production scalability. This focus on innovation not only elevates product quality but also creates opportunities for manufacturers seeking reliable, high-performance assembly solutions.

The Evolution of Hinge Assembly: From Manual to 3D

Traditional hinge assembly relied heavily on manual labor, leading to inconsistencies in 3D alignment—critical for applications like mobile devices, automotive doors, and furniture hinges. The shift to 3D hinge assembly technology emerged as a response to demands for tighter tolerances, smoother movement, and reduced part defects. However, integrating components in three-dimensional space presented unique hurdles: maintaining precision across multiple axes, minimizing assembly time, and adapting to diverse material properties (e.g., metals, plastics, composites).

Key Challenges in 3D Hinge Assembly

Manufacturers face three core challenges when scaling 3D hinge production:

1. Precision Alignment: Ensuring components align within micrometer-level tolerances to prevent jamming or premature wear.

2. Process Complexity: Coordinating multiple assembly steps (e.g., inserting pins, attaching covers, testing movement) without disrupting the 3D structure.

3. Scalability: Adapting to varying production volumes while maintaining quality, a critical factor for meeting market demands in fast-paced industries.

Jieyang Factory’s Innovations in 3D Hinge Assembly

Jieyang factories have addressed these challenges through targeted technological advancements:

- Automated Multi-Axis Systems: Leveraging collaborative robots (cobots) with 3D vision systems, these factories achieve real-time component detection and adjustment. For example, integrated cameras scan hinge parts in three dimensions, sending data to AI-driven control systems that adjust assembly tools to maintain precision.

- Modular Tooling Design: Customizable tooling setups allow quick adaptation to different hinge types, reducing setup time by up to 40% compared to traditional fixed-tool methods. This flexibility is key for manufacturers producing diverse hinge models.

- Material Compatibility Optimization: By analyzing material hardness and elasticity, engineers have developed specialized clamping mechanisms that prevent part deformation during assembly. This ensures consistent performance across materials like aluminum alloys and engineering plastics.

Real-World Applications of 3D Hinge Technology

The impact of these innovations is visible across industries:

- Consumer Electronics: 3D hinges enable slimmer, more durable mobile device designs, with Jieyang-fabricated hinges supporting 360° rotation and stress-free opening/closing.

- Automotive: In car interiors, 3D hinge assembly ensures smooth operation of center console lids and door panels, even under varying temperature and vibration conditions.

- Furniture Manufacturing: For telescopic drawer slides, 3D alignment guarantees seamless extension and retraction, enhancing user experience and product lifespan.

Sanyhore: Your Partner in Hinge and Slide Assembly Solutions

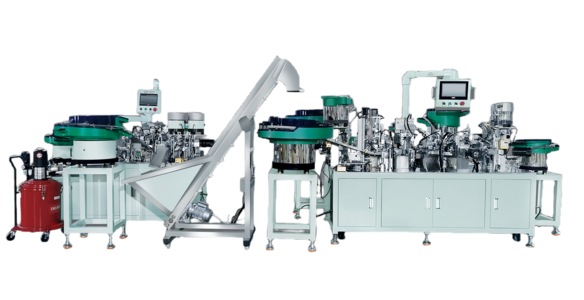

Behind these innovations lies Sanyhore, a professional manufacturer specializing in hinge assembly machines, telescopic drawer slide assembly machines, and roll forming machines. With a focus on 3D assembly technology, Sanyhore’s equipment integrates the latest advancements from Jieyang factories, delivering reliable, high-efficiency solutions for modern production lines. Whether you need to optimize hinge assembly processes or scale telescopic drawer slide production, Sanyhore’s machines are designed to meet your specific needs.

Conclusion and Call to Action

As 3D hinge assembly technology evolves, Jieyang factories and partners like Sanyhore continue to push boundaries, making manufacturing more precise, efficient, and adaptable. To explore how 3D hinge assembly machines or telescopic drawer slide assembly systems can transform your production, contact our sales manager at +86 13425506550 or email info@sanyhore.com. Let’s discuss your project requirements and find the right solution for your manufacturing goals.

Common SEO Questions for Sanyhore’s Website

1. What are the key advantages of 3D hinge assembly technology for modern manufacturers?

Answer: 3D hinge assembly enhances precision (±0.02mm tolerances), reduces manual errors, and supports diverse component integration, improving product reliability and production efficiency.

2. How does Sanyhore’s hinge assembly machine differ from standard equipment?

Answer: Our machines feature AI-driven 3D vision systems, modular tooling, and real-time quality control, ensuring consistent performance across varying hinge types and production volumes.

3. What role does roll forming play in telescopic drawer slide manufacturing?

Answer: Roll forming machines shape metal strips into precise slide rails, providing the structural strength and dimensional accuracy needed for smooth drawer movement, a critical step in Sanyhore’s telescopic slide assembly lines.

4. Which industries benefit most from 3D hinge assembly innovations?

Answer: Consumer electronics, automotive, furniture, and industrial equipment industries, where compact design, durability, and seamless movement are essential.

5. How can Sanyhore help optimize my hinge assembly process?

Answer: Our team designs custom solutions, integrating 3D assembly technology, roll forming machines, and telescopic slide assembly systems to align with your production goals, reducing costs and boosting output.

TDK:

标题:Jieyang’s 3D Hinge Assembly Breakthroughs: Redefining Modern Manufacturing Excellence

关键词:3D hinge assembly technology, Jieyang factory, hinge assembly machine, telescopic drawer slide assembly machine, roll forming machine

描述:Jieyang-based manufacturing facilities are driving innovation in 3D hinge assembly technology, integrating precision engineering with advanced automation to enhance production efficiency and product performance, supporting industries like consumer electronics and automotive.