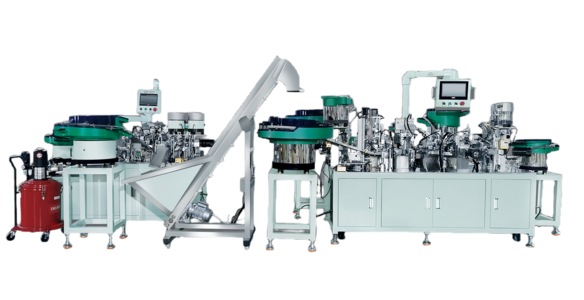

Sanyhore has established itself as a leading force in hydraulic precision engineering, specializing in the design and production of advanced assembly machines. With a focus on innovation and reliability, our machines—including hinge assembly machines, telescopic drawer slide assembly machines, and roll forming machines—are engineered to meet the rigorous demands of modern manufacturing. By integrating cutting-edge hydraulic technology with meticulous precision, we empower industries to enhance production efficiency, reduce errors, and achieve consistent, high-quality results. Whether for small-scale workshops or large-scale factories, Sanyhore’s machines are designed to elevate operational standards and drive business growth.

Understanding Hydraulic Precision in Assembly Systems

At the core of Sanyhore’s machines lies the power of hydraulic precision engineering. Hydraulic systems, known for their ability to deliver controlled, consistent force, form the backbone of our assembly processes. Unlike mechanical systems, hydraulic setups offer superior stability, allowing for micro-precise adjustments during assembly. This precision is critical in industries like furniture manufacturing, automotive parts production, and construction hardware, where even minor deviations can compromise product performance or safety. By leveraging hydraulic technology, Sanyhore ensures that each hinge, slide, or component meets exacting tolerances, minimizing waste and rework while maximizing product durability.

Core Product Lines: Engineering Hinges and Telescopic Slides

Sanyhore’s hinge assembly machines are designed to streamline the production of hinges, essential for furniture, doors, and cabinetry. Equipped with automated feeding systems and adaptive clamping mechanisms, these machines handle various hinge types—from small decorative hinges to heavy-duty industrial hinges—ensuring secure, uniform joints. Similarly, our telescopic drawer slide assembly machines focus on efficiency and reliability. Engineered to assemble multi-section telescopic slides, they integrate precision alignment tools and quality testing stations, guaranteeing smooth movement and long service life for drawer systems in residential and commercial settings. Both machines are customizable, allowing for integration with existing production lines and tailored to specific client requirements.

Roll Forming Technology: Shaping the Future of Slide Manufacturing

For the production of high-strength, consistent telescopic drawer slides, Sanyhore’s roll forming machines are unmatched. Roll forming is a continuous process that shapes metal sheets into complex profiles with minimal material waste. Our machines feature advanced roll tooling systems, computerized controls, and real-time monitoring, ensuring each slide meets strict dimensional standards. This technology not only boosts production speed but also enhances material utilization, reducing costs for clients. Whether manufacturing standard or custom slide profiles, Sanyhore’s roll forming machines deliver the precision and consistency needed for modern, high-performance drawer systems.

Beyond Machinery: Sanyhore’s Commitment to Client Success

Sanyhore doesn’t just sell machines—we provide solutions. Our team of engineers works closely with clients to understand their unique production challenges, offering technical support from initial design to after-sales service. From on-site installation and operator training to routine maintenance, we ensure that our machines remain reliable and productive throughout their lifecycle. This commitment to client success has made Sanyhore a trusted partner for manufacturers seeking to optimize their assembly processes.

FAQs: Your Questions Answered

Q: What makes Sanyhore’s assembly machines stand out?

A: Our focus on hydraulic precision, customizable designs, and post-purchase support sets us apart. Each machine is engineered for long-term reliability and adaptability to evolving production needs.

Q: Can your machines handle both standard and custom hinge/slide specifications?

A: Yes. Sanyhore offers tailored solutions, with adjustable parameters to accommodate different hinge sizes, slide lengths, and material types, ensuring flexibility for diverse client requirements.

Q: How do your roll forming machines impact production efficiency?

A: By enabling continuous, high-speed forming, our roll forming machines reduce production time by up to 30% compared to traditional methods, while minimizing material waste and ensuring consistent quality.

Q: Do you provide technical training for machine operation?

A: Absolutely. Our team offers comprehensive training sessions to ensure operators can maximize machine performance and troubleshoot basic issues, with ongoing support available.

Q: How can I get in touch to discuss my production needs?

A: Reach out to our sales team directly at +86 13425506550 or email info@sanyhore.com. We’ll schedule a consultation to understand your requirements and recommend the ideal assembly solution.

Ready to transform your manufacturing process? Contact Sanyhore today to explore how our hydraulic precision machines can drive efficiency and quality in your production line.