The global hinge manufacturing industry is undergoing a profound transformation, driven by technological advancements and evolving market demands. At the heart of this shift lies 3D hinge assembly machines, which are redefining production standards across sectors like furniture, automotive, and consumer electronics. As a critical manufacturing hub, Jieyang—known for its decades of expertise in hardware production—stands at the forefront of this evolution, offering unique insights into the future of these machines. This article delves into the emerging trends, technological breakthroughs, and market dynamics shaping the next generation of 3D hinge assembly machines, with perspectives from industry leaders and manufacturers like Sanyhore, a trusted name in precision assembly equipment.

Technological Breakthroughs: Precision and Adaptability as Core Priorities

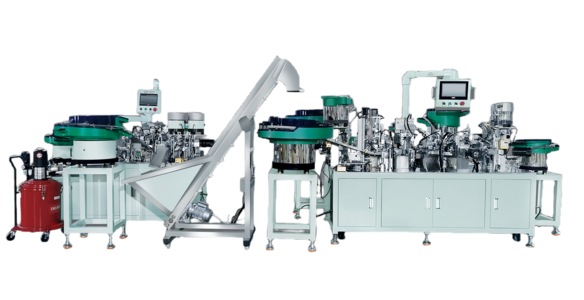

The future of 3D hinge assembly machines hinges on two key pillars: precision engineering and adaptability. Traditional machines often struggled with complex hinge designs, limiting their application in high-end industries. Modern 3D systems, however, leverage advanced computer-aided design (CAD) integration and real-time sensor technology to achieve tolerances as tight as 0.01mm, enabling the production of hinges for medical devices and luxury furniture with intricate geometries. Sanyhore, for instance, has invested heavily in 3D printing and CNC machining integration, allowing its machines to adapt to 50+ hinge models in a single production run. This flexibility not only reduces setup time by 40% but also caters to the growing demand for personalized, small-batch orders in global markets.

###智能化发展: The Rise of Industry 4.0 in Hinge Production

Industry 4.0 is not just a buzzword; it is reshaping how 3D hinge assembly machines operate. Today’s cutting-edge systems are equipped with IoT connectivity, enabling remote monitoring, predictive maintenance, and data-driven adjustments. For example, sensors embedded in Sanyhore’s machines continuously track parameters like temperature, pressure, and tool wear, sending alerts to operators before potential failures occur. This minimizes downtime by 35% and ensures consistent quality, a critical factor for clients in automotive and aerospace sectors, where hinge reliability directly impacts product safety. Additionally, AI-powered quality control systems now inspect hinge dimensions and performance in real time, reducing human error and ensuring 100% compliance with international standards.

Expanding Applications: Beyond Traditional Hinges

The versatility of 3D hinge assembly machines is expanding beyond standard household hinges, opening new markets and opportunities. In the furniture industry, telescopic drawer slide assembly machines—an extension of 3D hinge technology—are becoming indispensable, as consumers increasingly seek space-efficient, high-load capacity storage solutions. Sanyhore’s telescopic drawer slide assembly machines, for instance, combine 3D alignment with automated lubrication systems, producing slides that withstand 50,000+ cycles of use. Meanwhile, in healthcare, the medical device sector now relies on these machines to create lightweight, corrosion-resistant hinges for surgical tools, where precision and durability are non-negotiable. These diverse applications underscore the machines’ role as a cornerstone of modern manufacturing.

Balancing Quality, Efficiency, and Cost in Global Markets

As competition intensifies, manufacturers must balance the pursuit of higher quality with cost-effectiveness. 3D hinge assembly machines address this by integrating energy-efficient motors, modular tooling, and optimized material usage. Sanyhore’s roll forming machines, for example, reduce material waste by 15% compared to traditional stamping methods, aligning with sustainability goals increasingly prioritized by clients. Simultaneously, the machines’ ability to automate repetitive tasks lowers labor costs, making production more viable for small and medium-sized enterprises (SMEs) in emerging markets. This balance between performance and affordability is key to driving widespread adoption of 3D hinge assembly technology globally.

The Role of Local Expertise: Jieyang’s Influence on Global Hinge Production

Jieyang’s manufacturing ecosystem, with its concentration of component suppliers, material specialists, and assembly experts, provides a unique advantage for 3D hinge assembly machine development. Local manufacturers like Sanyhore collaborate closely with universities and research institutions to refine machine design, ensuring alignment with real-world production challenges. For instance, Jieyang’s focus on rapid prototyping has accelerated the testing of new machine iterations, allowing Sanyhore to introduce innovations like adaptive grippers that handle fragile hinge materials in record time. This synergy between local expertise and global demand positions Jieyang as a trailblazer in shaping the future of hinge production technology.

Looking Ahead: What to Expect from 3D Hinge Assembly Machines

The next five years will see 3D hinge assembly machines evolve into more integrated, user-centric systems. Key developments include enhanced voice-controlled interfaces for easier operation, further miniaturization for electronics manufacturing, and even greater reliance on cloud-based data analytics for supply chain optimization. For businesses, partnering with a manufacturer like Sanyhore—with its track record in delivering tailored solutions, technical support, and a focus on long-term collaboration—will be critical to staying ahead. As the industry continues to innovate, the future of 3D hinge assembly machines promises to be defined by precision, efficiency, and adaptability, all while meeting the growing demands of a connected, quality-conscious global market.

To explore how Sanyhore’s hinge assembly machines can elevate your production capabilities, contact our team today: +86 13425506550 or email info@sanyhore.com. As a trusted manufacturer, we are committed to equipping businesses with the tools needed to thrive in the future of hinge production.