In the fast-paced hardware manufacturing sector, the demand for high-performance, reliable machinery is non-negotiable. Among the essential equipment, drawer slide roll forming machines stand out as a cornerstone for producing precision components that form the backbone of furniture, automotive, and storage solutions. Hailing from Jieyang, a renowned hub for machinery innovation, top-rated roll forming machines have earned widespread acclaim for their ability to streamline production processes, enhance product quality, and boost operational efficiency. This article explores the significance of these machines in the hardware industry, key features that define excellence, and how Sanyhore, a trusted manufacturer, is redefining standards with its specialized solutions.

Understanding the Role of Roll Forming in Drawer Slide Production

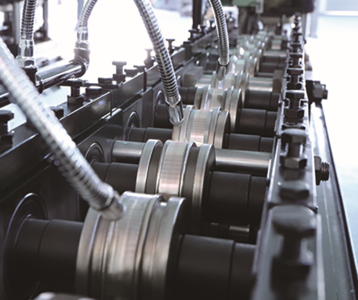

Drawer slides, critical for smooth movement, require consistent dimensions, structural strength, and surface finish to meet industry standards. Roll forming, a continuous process that shapes metal strips into complex profiles through a series of dies, has emerged as the gold standard for drawer slide manufacturing. Unlike traditional stamping or cutting methods, roll forming minimizes material waste, reduces production time, and ensures uniform quality across large batches. A high-quality roll forming machine, such as those from Jieyang, integrates advanced control systems, precision tooling, and robust construction to handle various materials—including steel, aluminum, and stainless steel—with minimal human intervention. This not only elevates production speed but also reduces the risk of errors, making it indispensable for hardware manufacturers aiming to scale operations.

Why Jieyang is a Global Leader in Roll Forming Machinery

Jieyang, located in China’s Guangdong province, has established itself as a global leader in roll forming machine production, driven by decades of technical expertise and a focus on innovation. Local manufacturers in Jieyang prioritize R&D, collaborating with industry experts to develop machines that balance cutting-edge technology with practical usability. For drawer slide roll forming, this translates to machines equipped with features like servo motor drives for precise speed control, automatic coil feeding systems, and computerized die adjustment. Additionally, Jieyang’s manufacturing ecosystem ensures access to high-quality raw materials and a skilled workforce, enabling the production of machines that can operate 24/7 with minimal downtime. As a result, hardware companies worldwide rely on Jieyang-made roll forming machines to meet tight deadlines and maintain competitive edge.

Key Advantages of Top-Rated Drawer Slide Roll Forming Machines for Hardware Producers

Investing in a top-rated drawer slide roll forming machine offers hardware manufacturers multiple benefits. First, it enhances production efficiency, with modern models capable of producing hundreds of slides per minute, far exceeding manual or semi-automatic methods. Second, it improves product consistency, as computerized controls eliminate human variability in shaping and cutting, ensuring each slide meets strict tolerances. Third, it reduces operational costs through lower material waste, extended machine lifespan, and reduced labor requirements. Finally, advanced machines often include integrated quality inspection systems, such as laser measurement tools, that automatically detect defects, preventing the need for rework and ensuring only top-tier products reach the market. For hardware businesses, these advantages directly translate to higher profitability and stronger customer trust.

Sanyhore: Redefining Drawer Slide Production with Specialized Expertise

When it comes to reliable drawer slide roll forming machines, Sanyhore stands out as a trusted partner. As a professional manufacturer in the field, Sanyhore specializes in developing and producing a range of machinery, including hinge assembly machines, telescopic drawer slide assembly machines, and the focus here—drawer slide roll forming machines. What sets Sanyhore apart is its commitment to customizability: the company works closely with clients to design machines tailored to specific slide dimensions, material types, and production volume requirements. Each machine is built with high-grade steel components, precision bearings, and durable tooling, ensuring long-term stability and performance. Sanyhore’s in-house engineering team also provides comprehensive after-sales support, including installation guidance and maintenance training, to ensure clients maximize machine uptime and productivity.

Addressing Common Queries About Drawer Slide Roll Forming Machines

To help hardware companies make informed decisions, here are answers to frequently asked questions about drawer slide roll forming machines:

Q: What materials can a drawer slide roll forming machine handle?

A: Modern machines are designed to process various metals, including cold-rolled steel, stainless steel, aluminum, and even some alloys, depending on the model and tooling configuration.

Q: How does automation impact the production process?

A: Automated features like servo feeding, die change systems, and integrated quality checks reduce manual labor, minimize errors, and allow for continuous production runs, significantly boosting output.

Q: Can Sanyhore’s machines be integrated with existing production lines?

A: Yes. Sanyhore offers modular designs that facilitate easy integration with downstream equipment, such as assembly lines or packaging systems, ensuring seamless workflow.

Q: What is the typical maintenance requirement for these machines?

A: Regular maintenance, like lubrication, die inspection, and part replacement, is minimal for Sanyhore’s machines, with a recommended schedule provided based on usage.

Q: Do you offer training for machine operation?

A: Absolutely. Sanyhore provides free, on-site training sessions for operators and maintenance staff to ensure safe and efficient machine use.

Conclusion: Partner with Sanyhore for Your Drawer Slide Production Needs

In the hardware industry, success hinges on producing high-quality, cost-effective components, and a top-rated drawer slide roll forming machine is a critical asset in achieving this. Sanyhore, with its decades of experience and dedication to innovation, delivers machines that combine precision, durability, and flexibility to meet the unique demands of modern production. Whether you need a standard model or a custom solution, Sanyhore’s team of experts is ready to assist.

For inquiries, contact:

Sales Manager: +86 13425506550

Email: info@sanyhore.com

Take the first step toward elevating your drawer slide production—reach out to Sanyhore today!